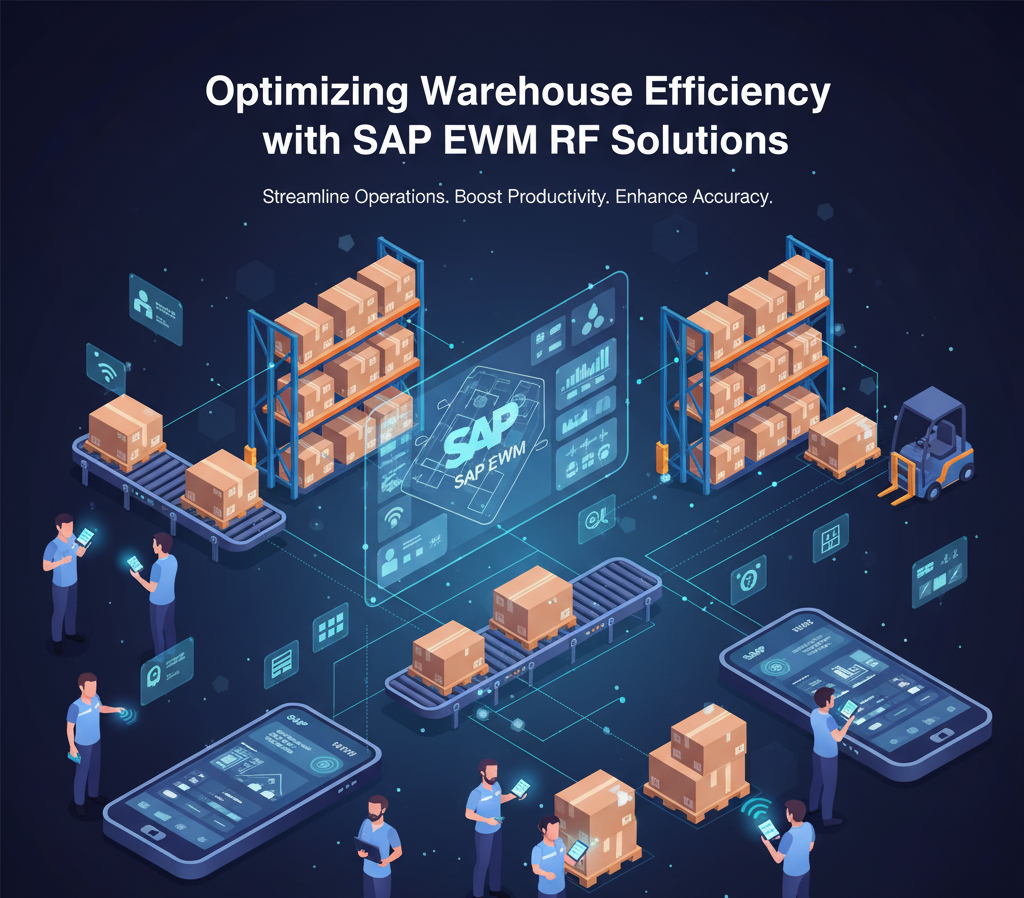

Optimizing Warehouse Efficiency with SAP EWM RF Solutions

In today’s fast-paced business environment, efficient warehouse management is no longer just a competitive advantage—it’s a necessity. For enterprises across the United States, optimizing warehouse operations can mean faster order fulfillment, reduced operational costs, and improved customer satisfaction. However, managing complex warehouse processes, including inventory tracking, order picking, and shipping, poses significant challenges. Traditional manual methods often lead to errors, delays, and inefficiencies that can affect the entire supply chain. This is where SAP Extended Warehouse Management (EWM) RF solutions come into play, transforming warehouse operations through automation and mobile technology.

Understanding the Challenges in US Warehouses

Warehouses in the United States face a multitude of challenges as they strive to meet growing consumer demands and e-commerce expectations. Some common pain points include:

-

Complex Inventory Management: Managing large volumes of SKUs across multiple locations can be overwhelming. Manual processes can result in inaccuracies, stockouts, or overstocking.

-

Slow Order Fulfillment: Traditional paper-based processes for picking, packing, and shipping often delay order processing and lead to dissatisfied customers.

-

High Operational Costs: Labor-intensive processes not only slow down operations but also increase operational costs.

-

Limited Visibility: Without real-time data, managers struggle to track inventory accurately, make informed decisions, or respond quickly to changes in demand.

To address these challenges, enterprises are increasingly turning to warehouse automation solutions. Among these, SAP EWM with RF mobile solutions stands out as a powerful tool for enhancing operational efficiency.

What is SAP EWM RF?

SAP Extended Warehouse Management (EWM) is a comprehensive warehouse management solution that provides advanced tools for inventory management, warehouse automation, and process optimization. When integrated with Radio Frequency (RF) mobile devices, SAP EWM enables warehouse staff to perform tasks directly at the point of activity, such as scanning barcodes, tracking inventory, and confirming orders.

The RF technology allows real-time communication between mobile devices and the SAP EWM system. This ensures that inventory data is updated immediately, reducing errors and improving accuracy. MobGUI, SAP’s mobile graphical user interface, simplifies the interaction between warehouse workers and the system, making tasks like picking, packing, and stock transfers faster and more efficient.

How SAP EWM RF Streamlines Warehouse Operations

Implementing SAP EWM RF solutions transforms warehouse operations in several ways:

1. Real-Time Inventory Tracking

RF devices allow warehouse staff to scan items at the time of receipt, movement, or shipment. This ensures that inventory levels are always accurate and up-to-date in the SAP EWM system. Real-time tracking eliminates the need for manual stock counts and reduces discrepancies between actual and recorded inventory.

For example, when goods are received in the warehouse, an RF device can scan the barcode on each item and automatically update the system. Similarly, when items are picked for an order, the system immediately reflects the change in stock levels. This real-time visibility allows warehouse managers to make better decisions, reduce stockouts, and optimize inventory levels.

2. Enhanced Picking and Packing Processes

Order fulfillment is one of the most critical warehouse operations. SAP EWM RF solutions optimize picking and packing through guided workflows on RF mobile devices. Workers receive instructions on the device for the most efficient picking path, reducing walking time and improving productivity.

MobGUI provides intuitive interfaces for tasks such as wave picking, batch picking, or zone picking. Workers can scan items during picking, confirm quantities, and move items to packing stations seamlessly. The system also allows for quality checks and error detection, ensuring that customers receive the correct products.

3. Efficient Warehouse Movements

Warehouses often involve complex internal movements, such as relocating stock between storage bins, staging areas, and shipping docks. SAP EWM RF devices enable workers to manage these movements efficiently. Each movement is tracked in real-time, providing managers with complete visibility of warehouse operations.

This capability is particularly useful for high-volume warehouses where quick replenishment and order staging are essential. Automated movement tracking reduces delays, ensures accurate inventory allocation, and minimizes the risk of misplaced goods.

4. Reduced Operational Errors

Manual processes in warehouses are prone to errors such as picking the wrong product, misplacing items, or incorrect documentation. SAP EWM RF solutions drastically reduce such errors by providing step-by-step instructions and automated validations. Workers receive instant feedback on the device, preventing mistakes before they occur.

For instance, if a worker scans the wrong product for an order, the system immediately flags the error and provides corrective instructions. This not only improves accuracy but also enhances customer satisfaction by ensuring timely and correct deliveries.

5. Streamlined Reporting and Analytics

With SAP EWM RF solutions, all warehouse activities are recorded in real-time, creating a rich dataset for analysis. Managers can generate reports on key metrics such as picking efficiency, inventory turnover, and order fulfillment rates. These insights help identify bottlenecks, optimize processes, and plan resources more effectively.

Advanced analytics can also forecast demand, highlight slow-moving inventory, and recommend storage strategies. This proactive approach ensures that warehouses operate efficiently and can adapt to changing business needs.

Real-Life Case Studies

Several US enterprises have successfully implemented SAP EWM RF solutions to transform their warehouse operations:

-

Global Electronics Distributor: By integrating RF devices with SAP EWM, the distributor reduced picking errors by 40% and improved order fulfillment speed by 30%. Real-time inventory updates allowed for better stock management and reduced carrying costs.

-

E-Commerce Retailer: A large online retailer implemented MobGUI-based RF solutions for its high-volume fulfillment centers. The guided picking workflows minimized walking distances and optimized packing, leading to a 25% increase in productivity and faster shipping times.

-

Pharmaceutical Warehouse: A pharmaceutical company faced strict compliance requirements for inventory tracking. SAP EWM RF enabled precise tracking of batch numbers and expiration dates, ensuring regulatory compliance while reducing manual effort.

These examples demonstrate how SAP EWM RF solutions can deliver tangible benefits across different industries, from reducing errors to improving overall warehouse efficiency.

Future Trends in Warehouse Automation

The evolution of warehouse automation continues to accelerate, driven by technological advancements and changing consumer expectations. Key trends shaping the future include:

-

Integration with IoT Devices: Internet of Things (IoT) sensors in warehouses can provide real-time data on temperature, humidity, and equipment status. Combined with SAP EWM RF solutions, this data can further optimize inventory management and storage conditions.

-

AI and Machine Learning: Predictive analytics powered by AI can anticipate demand patterns, optimize picking routes, and recommend inventory replenishments. Machine learning algorithms can continuously improve warehouse processes based on historical data.

-

Robotic Process Automation: Autonomous mobile robots (AMRs) are increasingly used to move goods within warehouses. When integrated with SAP EWM RF systems, these robots can work alongside human workers, enhancing efficiency and reducing labor costs.

-

Cloud-Based Solutions: Cloud deployment of SAP EWM allows for seamless updates, remote monitoring, and integration with other enterprise systems. This enhances scalability and reduces IT infrastructure costs.

-

Enhanced Mobility: Future mobile solutions will offer more intuitive interfaces, voice-guided picking, and augmented reality (AR) support, making warehouse tasks even faster and more accurate.

Conclusion

In an era where speed, accuracy, and efficiency define business success, SAP EWM RF solutions offer a powerful answer to the challenges faced by US warehouses. By enabling real-time inventory tracking, streamlining picking and packing processes, reducing operational errors, and providing actionable insights, SAP EWM RF transforms warehouses into highly efficient, automated operations.

Enterprises that adopt these solutions not only improve operational efficiency but also enhance customer satisfaction, reduce costs, and prepare for future trends in warehouse automation. As technology continues to evolve, warehouses that leverage SAP EWM RF and MobGUI will remain at the forefront of innovation, achieving a competitive edge in a demanding market.