Deep Technical & EWM RF Architecture: A Complete Guide for Modern Warehouses

Modern warehouses depend heavily on SAP EWM RF (Extended Warehouse Management – Radio Frequency) to run high-volume, error-free operations. With increasing demand for speed, accuracy, and mobility, enterprises in the US are shifting from paper-based workflows to RF-driven operations. Technologies like MobGUI, custom RF screens, SAP BAPIs, and hardware scanner integrations have become essential building blocks for real-time warehouse automation.

This blog explores the complete technical architecture behind SAP EWM RF and explains how advanced optimization techniques enhance performance for high-volume enterprises.

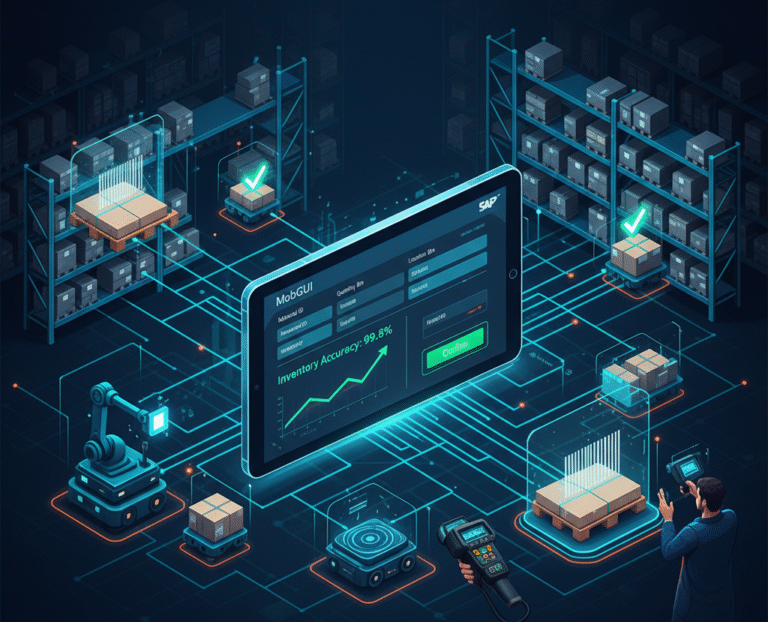

1. The Complete Architecture of SAP EWM RF Framework: How MobGUI Enhances Performance

The SAP EWM RF Framework is a modular, flexible, and high-speed mobile environment built to support warehouse operators using handheld RF devices. The traditional SAP ITS Mobile interface often struggles with speed and usability. This is where MobGUI for EWM RF becomes a game changer.SAP EWM RF Architecture Components

- SAP EWM Backend (SAP S/4HANA or SCM) Handles all business logic, warehouse tasks, bin management, inventory posting, and confirmations.

- RF Framework (SAP Delivered) Manages menu structures, logical transactions, user authorizations, and device sessions.

- ITS Mobile or MobGUI Layer

- ITS Mobile: Plain HTML, limited UI, slower transitions.

- MobGUI: Faster UI rendering, JavaScript support, modern widgets, and zero-lag screen transitions.

- RF Devices Handheld terminals, scanners, tablets, or rugged mobile devices.

- Wireless Network Infrastructure Ensures uninterrupted connectivity inside the warehouse.

How MobGUI Enhances Performance

- Reduced screen load time through optimized rendering.

- Mobile-responsive UI that fits any screen size.

- Improved operator speed due to better usability.

- Supports features like dropdowns, buttons, multi-input fields, which are difficult in ITS Mobile.

- Lower error rates due to guided workflows.

Best UX Practices for EWM RF

a) Keep Screens Minimal and Action-Focused

Warehouse operators should not type unless required. Use:- Pre-filled fields

- Automatic defaults

- One-click buttons

b) Use Large Buttons and High-Contrast Colors

- Operators use the device while walking or picking.

- Large actionable areas reduce mis-clicks.

c) Reduce Navigation Steps

- Avoid complex menus.

- Design linear, guided workflows.

d) Enable Scan-to-Input Everywhere

- RF devices are scanner-first machines.

- Every input field should support barcode scanning.

e) Avoid Overloading the Screen

Show only needed information:- Task

- Bin

- Material

- Quantity

How to Optimize RF Queue Management for High-Volume Warehouses

For warehouses handling thousands of tasks per hour, RF queue optimization is crucial. Poor queue design leads to delays, bottlenecks, and idle operators.Key Techniques for RF Queue Optimization

a) Dynamic Queue Assignment

Assign tasks based on:- Operator skill

- Current workload

- Task priority

- Travel distance

b) Use Resource Groups and Queue Filters

Create separate queues for:- Picking

- Putaway

- Replenishment

- Packing

c) Prioritize Short-Distance Tasks

Optimizing travel time reduces operating costs.d) Monitor Queue Load in Real Time

Use SAP EWM monitoring tools to:- Identify stuck queues

- Resolve locked tasks

- Balance workload

e) Apply “Pick-to-Clear” Logic

This helps consume partial bins first, improving bin utilization. By combining SAP capabilities with custom logic, high-volume warehouses achieve smooth task distribution and reduce processing times.4. The Role of SAP BAPIs and Function Modules in Custom RF Transactions

Custom RF transactions rely heavily on backend components like SAP BAPIs, Function Modules (FMs), and Business Add-Ins (BADIs). They enable custom logic and seamless integration with EWM processes.Why BAPIs and FMs Are Essential

- Real-Time Processing

- Confirm warehouse tasks

- Update stock quantities

- Perform bin scans

- Data Validation Ensures scanned data is correct before confirmation.

- Custom Business Logic Adapt SAP processes based on enterprise requirements.

Common BAPIs Used in EWM RF

- /SCWM/TO_CONF – Confirm warehouse tasks

- /SCWM/WHSE_TASK_GET – Retrieve open tasks

- /SCWM/MOVE_BIN – Move stock between bins

Function Modules for Custom RF

- /SCWM/RFUI_READ_LGTYP – Reads storage type configuration

- /SCWM/RF_DETERMINE_NEXT_TASK – Determines next RF task

- Custom Z-FMs – For advanced workflows like wave picking or multi-stage scanning

Key Integration Requirements

a) Device Compatibility

Devices should support:- Android OS (latest recommended)

- HTML5

- Wi-Fi 5 or Wi-Fi 6

- Enterprise barcode scanning SDK

- Zebra

- Honeywell

- Datalogic

b) Scan Engine Support

MobGUI offers better scanning compatibility than ITS Mobile. Supports:- 1D/2D barcode scanning

- QR code

c) Network Stability

RF devices must have:- 100% Wi-Fi coverage

- Roaming support

- Low latency

d) Security Integration

Support for:- VPN

- SSO

- MDM (Mobile Device Management)

e) Custom API-Level Integrations

Needed when using:- Conveyor systems

- Robotics

- Automated picking systems

- IoT devices